The STRYDE limb lengthening nail is susceptible to mechanically assisted crevice corrosion: an analysis of 23 retrieved implants

DOI:

https://doi.org/10.1080/17453674.2021.1927506Abstract

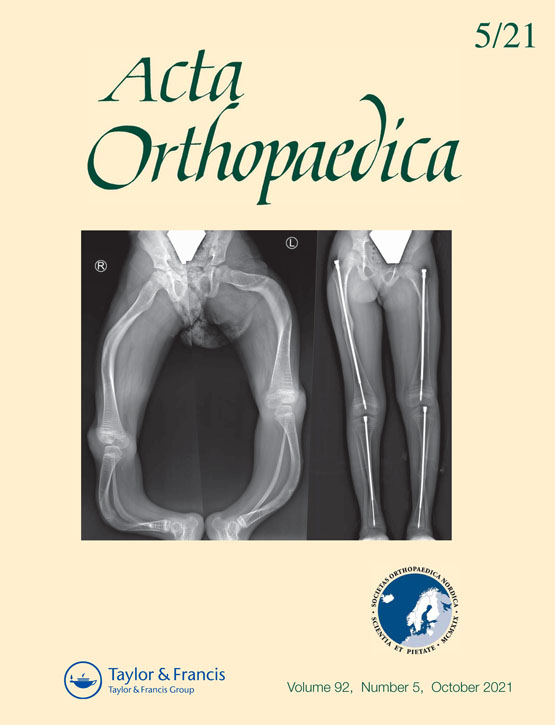

Background and purpose — We noted several adverse events in patients in whom the first version of the STRYDE limb-lengthening nail (NuVasive Specialized Orthopaedics, San Diego, CA) had been implanted. Pain, osteolysis, peri- osteal reactions, and cortical hypertrophy at the nail junc- tion were noted. Here, we present the analysis of 23 retrieved STRYDE implants.

Materials and methods — We undertook visual inspec- tion of the retrieved nails and screws, mechanical evaluation of the junction, micro-CT analyses, microscopic inspection of the bushing, screws, screw holes, and separated parts of the implants. Positive material identification (PMI) and energy-dispersive X-ray spectroscopy (EDS) were used to analyze the chemical composition. The hardness of the mate- rial was also investigated.

Results — 20/23 retrieved nails had visible signs of cor- rosion, i.e., discoloration at the telescopic junction. Micro- CT verified corrosion attacks in 12/12 scanned bushings. Corrosion, predominantly mechanically assisted crevice corrosion, was observed at the locking screws and screw holes in 20/23 nails. Biological material inside the nail was observed in addition to oozing from the junction of 2 nails during hardware removal, which was experimentally repro- ducible. Notably, the mechanical construction of the bushing changed from PRECICE P2 to STRYDE nails.

Interpretation — STRYDE nails are not hermetically sealed, and liquid can pass the bushing. Biodur 108 itself is corrosion resistant; however, mechanically assisted crev- ice corrosion of the bushing, locking screws, and screw holes may be aggravated due to manufacturing aiming for increased strength and hardness of the alloy.

Downloads

Downloads

Additional Files

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Jan Duedal Rölfing, Morten Stendahl Jellesen, Trine Nybo Lomholt, Rikke Quist Hansen, Troels Mathiesen, Carsten Gundlach, Søren Kold, Tobias Nygaard, Mindaugas Mikuzis, Ulrik Kähler Olesen

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.